Time-of-flight diffraction (TOFD), a method of advanced ultrasonic testing, is a sensitive and accurate method for the non-destructive testing of welds for defects. Although not exclusively used for welds, it is very effective in detecting most types of weld defects such as cracks, lack of fusion and slag inclusion.

ToFD is Fast - With a High Degree of Repeatability

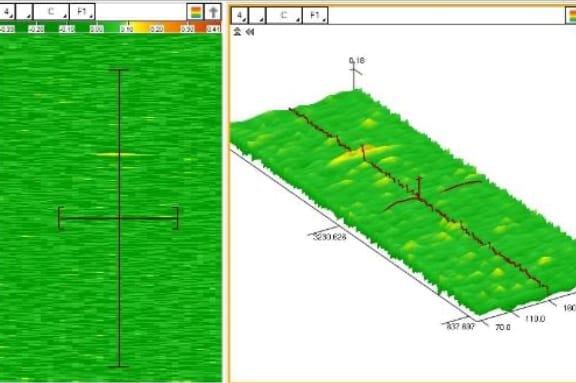

ToFD is one of the fastest methods of advanced non-destructive testing because, unlike other types of UT methods, generally only one scan is required to find any defect information within the weld. It can locate and measure the size of many different types of defects with incredible precision. It also has a high degree of repeatability. Because of this, the growth of any flaws can be monitored over time.

Detects the Extremities of Defects Regardless of Orientation

One of the main benefits of using TOFD over pulse echo ultrasonic techniques, such as phased array and conventional ultrasonic testing, is that it relies on the detection of the diffracted wave mode rather than reflected energy, therefore can be viewed as omnidirectional. It detects the extremities of defects regardless of orientation making it ideal for detecting and sizing defects such as cracks, where the orientation of the defect may not cause a sufficient reflected energy and may go undetected by the technician.

ToFD is also an excellent tool for the detection and measurement of root erosion/corrosion surveys and is a complementary technique used alongside Phased Array for weld volume inspection.