Phased array ultrasonic testing (PAUT) provides detailed visualisations of vessels, pipes or other infrastructure without the need to halt production – or establish safe zones to protect your staff from ionising radiation.

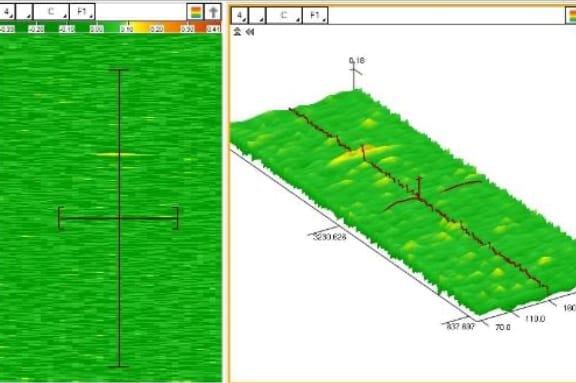

The technique is accurate, and allows you to quickly map the size, shape, depth and orientation of corrosion, cracks, flaws and other defects. It’s also cost-effective, and provides data in real-time, allowing our inspection personnel to analyse your equipment/infrastructure and produce a detailed inspection report in a matter of hours.

Energy sector clients call on us to conduct phased array ultrasonic testing when they need to carry out:

- Weld inspections

- Corrosion mapping

- Bolt and nozzle inspections

- Structural assessments

- Fitness-for-service assessments

- Flaw analysis

- Engineering critical assessments (ECAs)

We also provide phased array inspection services for new-build fabrication and assembly projects where there’s a need to test or certify the integrity of piping, pipelines, vessels, and structural welded members.