Background

Our client, a UK independent oil and gas company, required a solution for a damaged subsea flange. The damage was on the high-pressure sealing area.

Based on Glacier Energy’s expertise and track record in the field, the client approached our machining solutions division for expert advice on the optimum solution to repair the flange, regardless of how deep the damage was.

Scope

Based on the urgent nature of the project, the machine was fast-tracked and delivered within 18 weeks.

In addition to designing and manufacturing the bespoke equipment, the team carried out FATs, a SIT and diver training at Glacier Energy’s premises in Glasgow, UK. Glacier Energy’s Machining Solutions team also project managed the supply of the subsea hydraulic drive system.

A team of two technicians were then mobilised to work with the dive control team to assist with technical input. From deployment of the machine to the seabed, through to the recovery of the machine back on the deck, the operation took less than 30 hours. During this time, electronic laser equipment was used to confirm the sealing area had been machined to the correct tolerances, and the damage had been removed.

Solutions

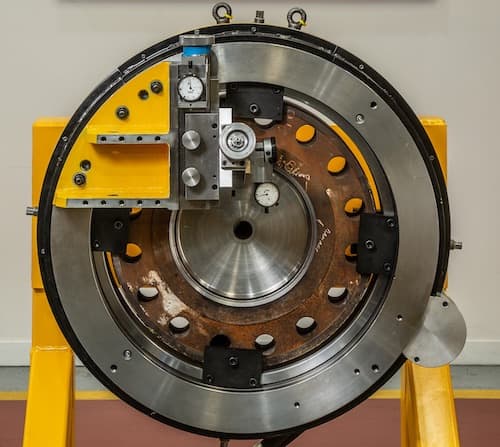

Using our in-house design and manufacturing expertise, Glacier Energy developed a bespoke subsea flange facing machine. The solution needed to be diver and environmentally friendly whilst also ensuring complete accuracy of the machined repair.

Benefits

- Saving of £ms as the operation was completed successfully during the planned campaign window

- Accurate machining at 140m water depth

- Highest standards of quality, speed, and accuracy

- Diver operated and environmentally friendly

- Speed of response from original enquiry

- Fully integrated service from concept through to completion

- Single source provider with all disciplines under one roof

"I would like to pass on my thanks for the excellent work of your offshore personnel. Both technicians were very professional in their approach to the work, even with the time it took to set up the machine with the divers. The design of the equipment was excellent and that was proven with the result we achieved. It’s been a pleasure working with your team & we will be in touch if we have similar future projects."